Friction Stir Welding (FSW)

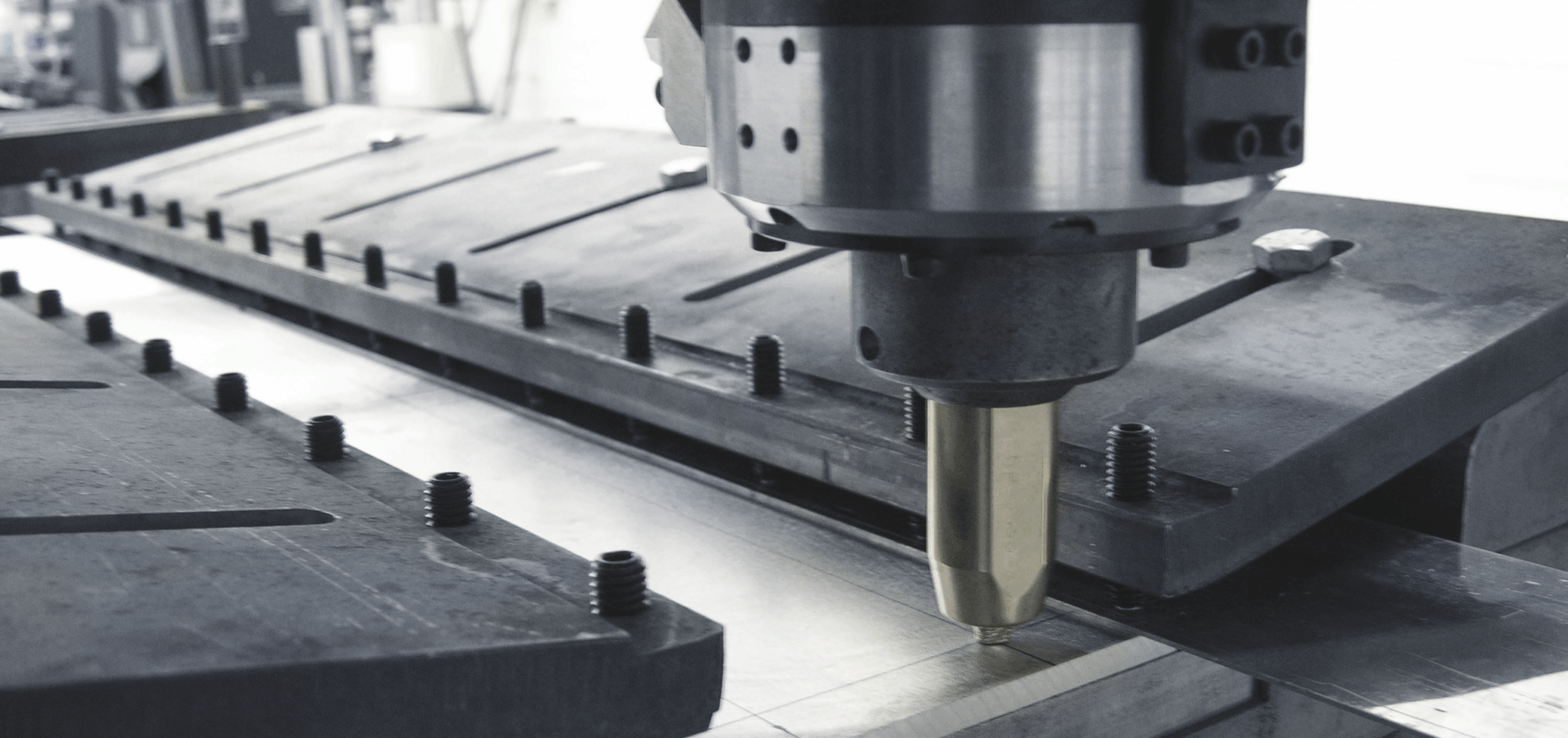

Custom Spindles for Modern CNC and Robotic Manufacturing Systems

Friction Stir Welding (FSW)

is an innovative welding process that uses frictional heat to join materials in the solid state. Unlike conventional fusion welding, FSW does not melt the material but plastifies it, resulting in high joint strength and minimal distortion.

Key Features of the CYTEC FSW System Components.

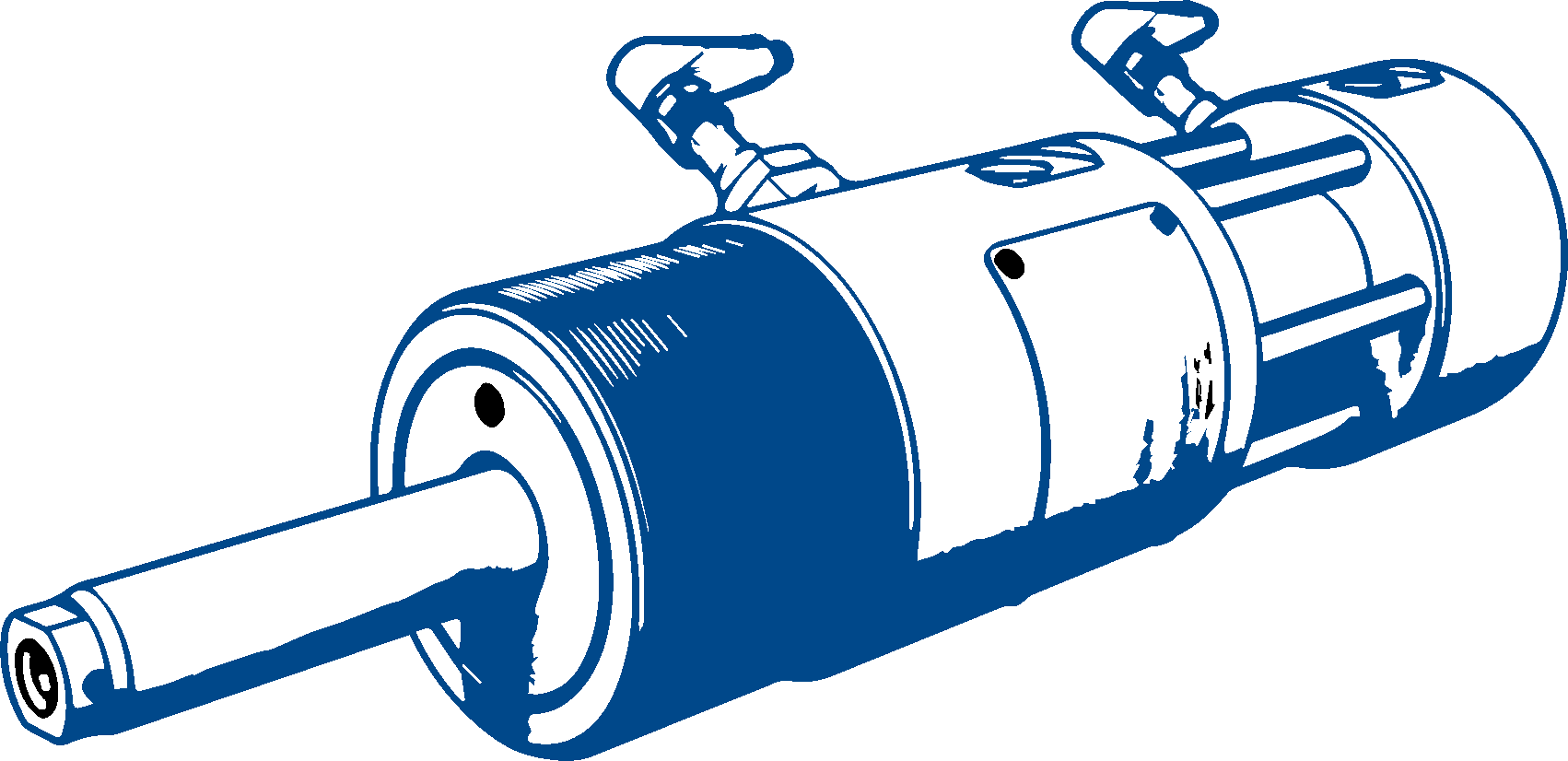

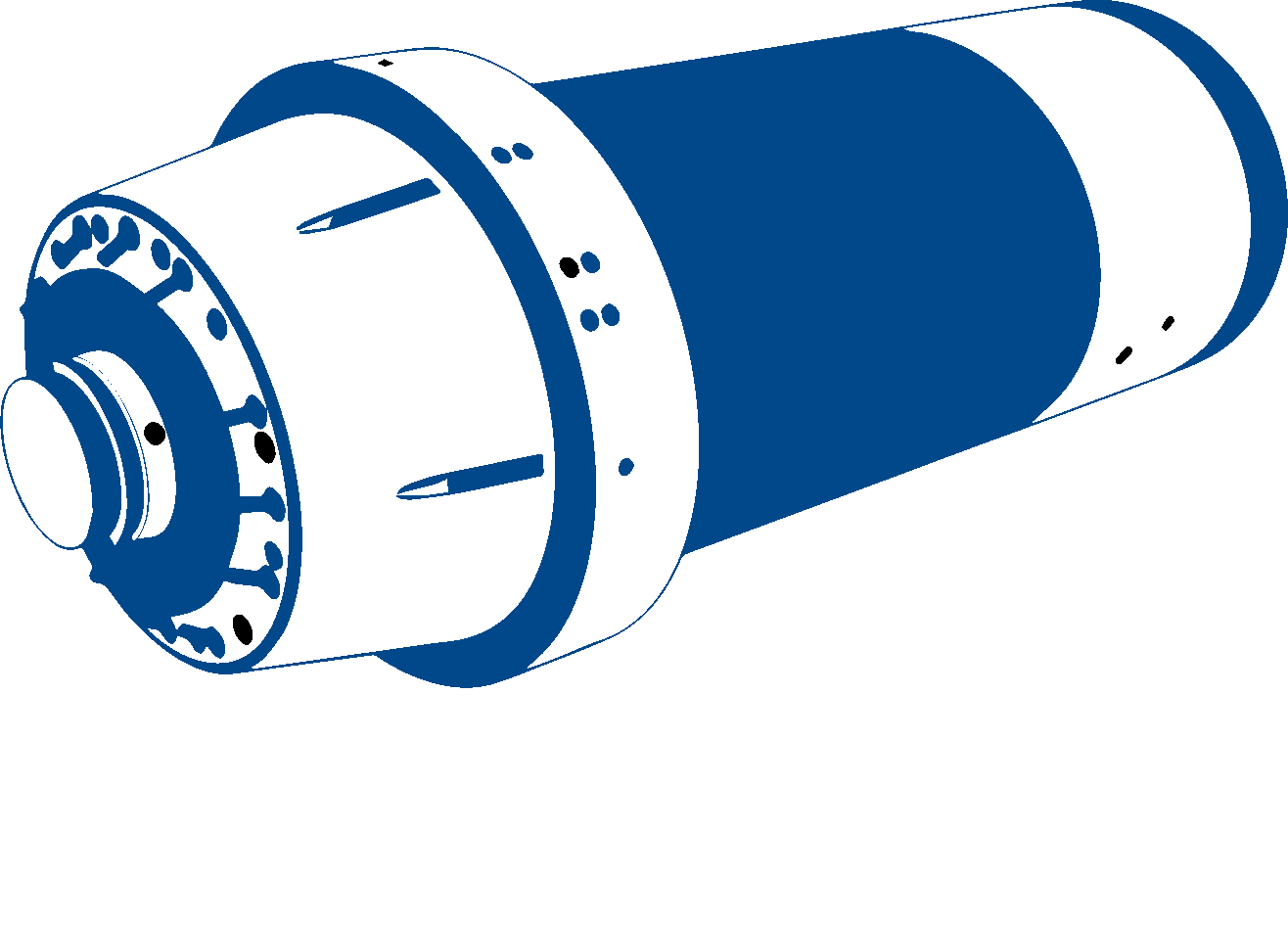

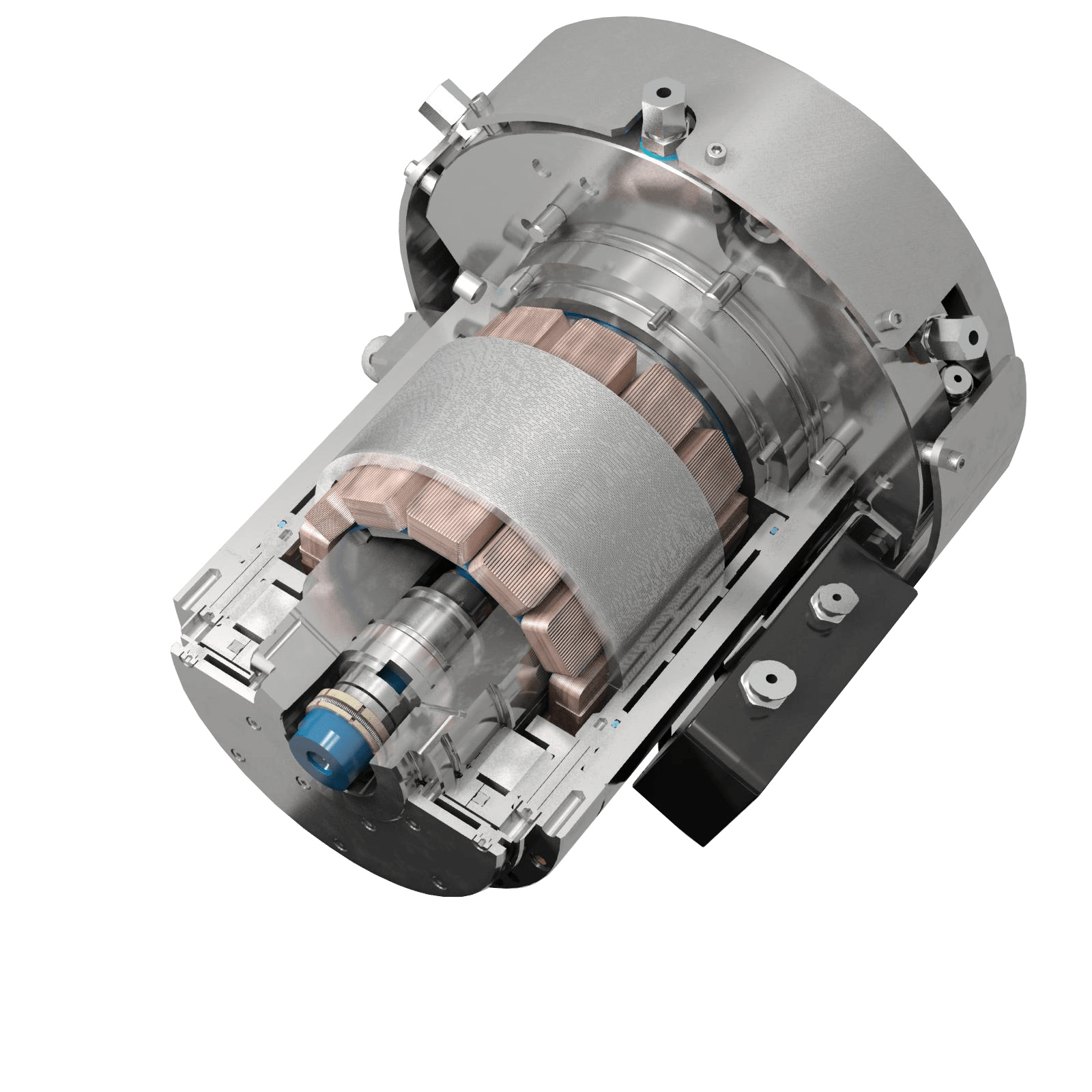

Spindle Components:

HSK tool holder with positive hydromechanical clamping system, spindle torque motor, and preloaded hybrid bearings.

Force Control System:

Automatic clamping system, analog flow meters combined with electronic evaluation unit.

Tool Technologies:

Flextool for high surface quality and reduced process forces.

Precise control of process forces is crucial for weld quality. The FSW spindles are equipped with shear force sensors that detect axial deviations during the welding process across the entire 360° range. This ensures reliable and safe force regulation in any situation.

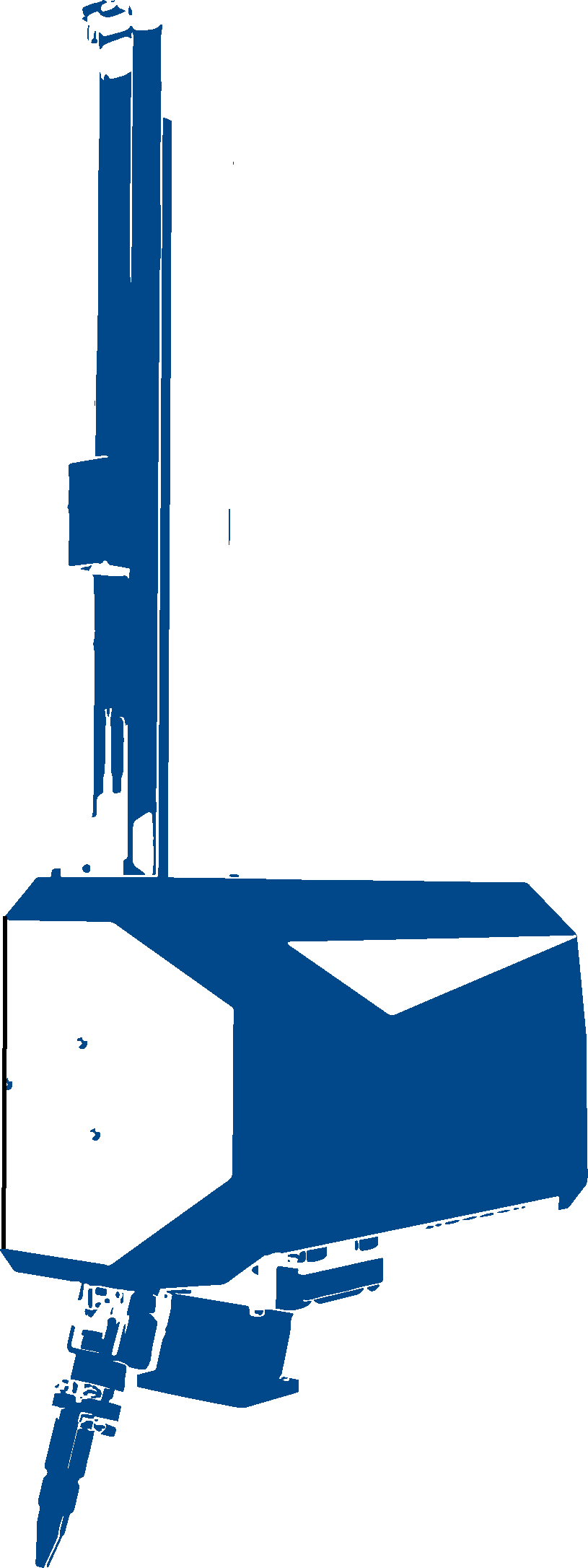

Friction Stir Welding (FSW)

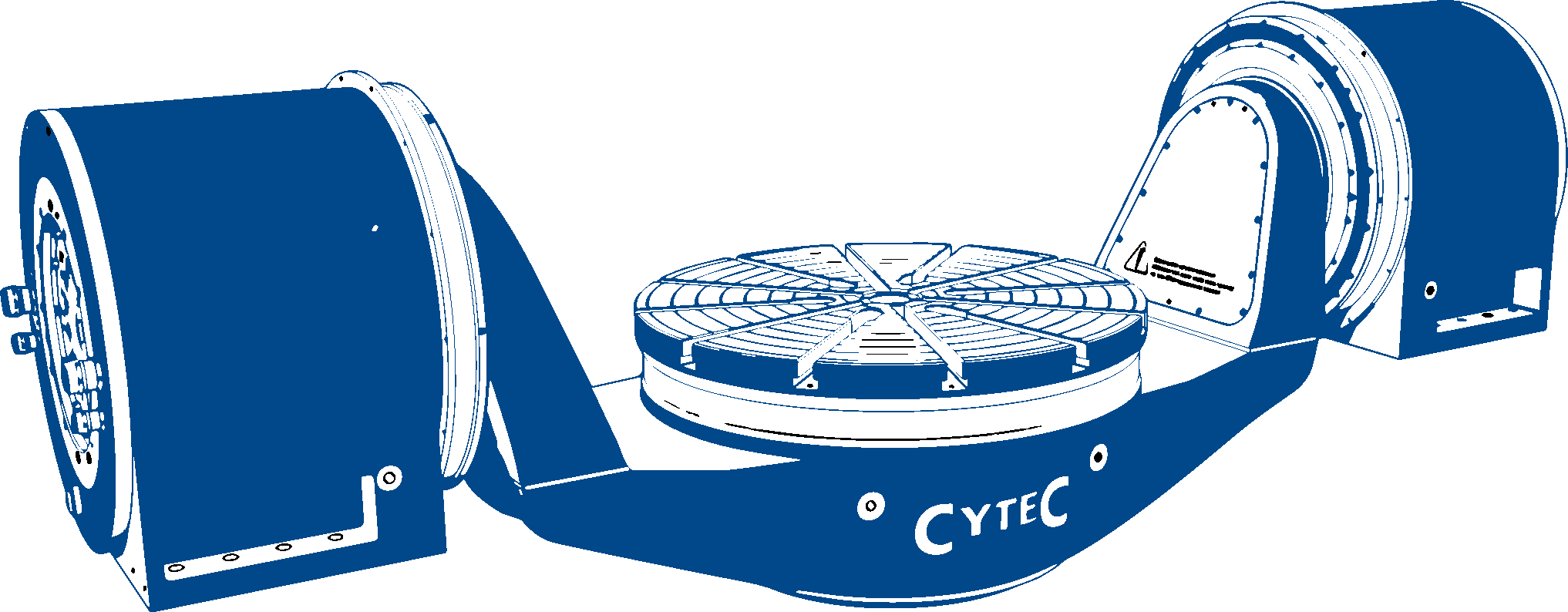

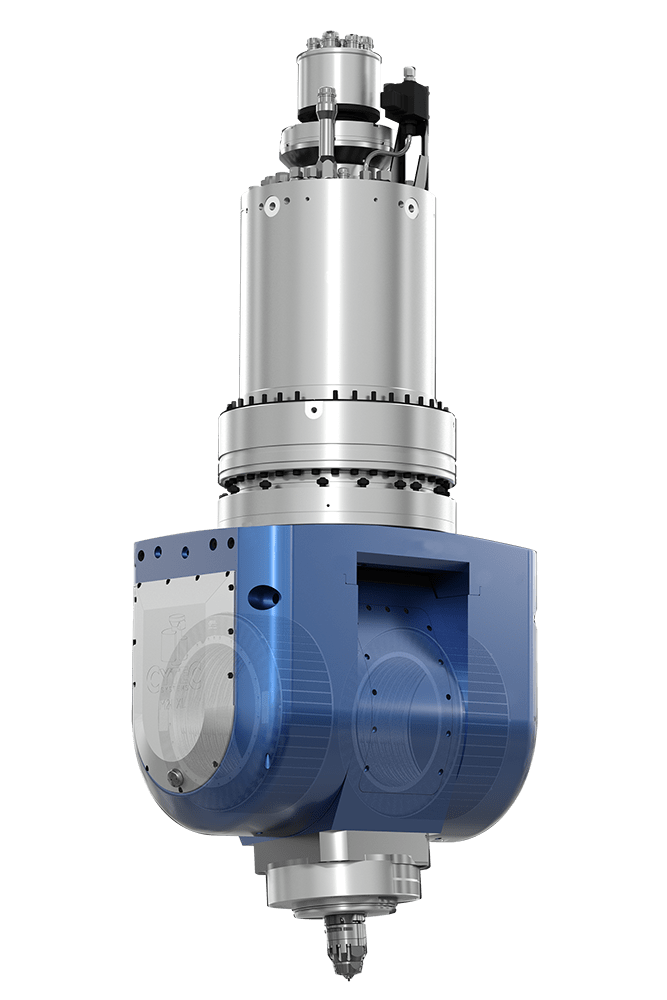

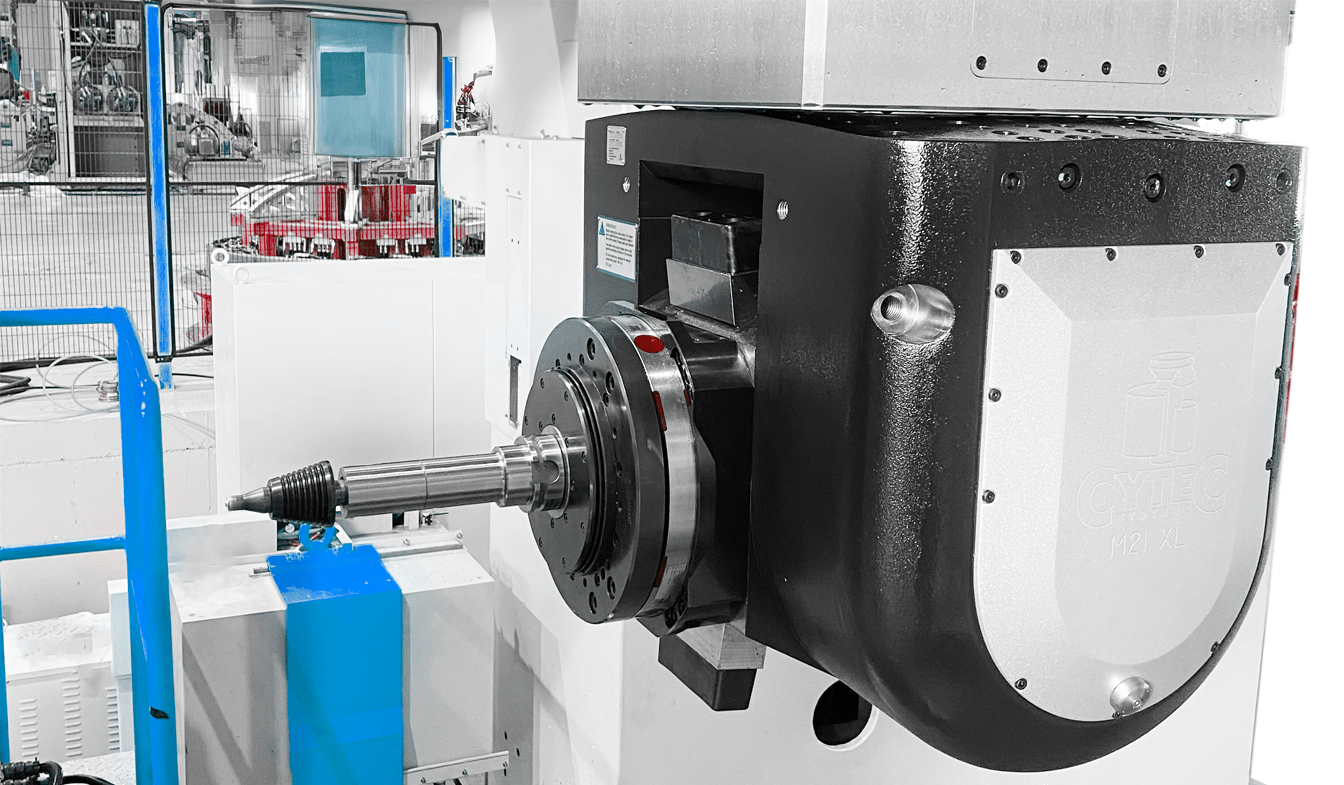

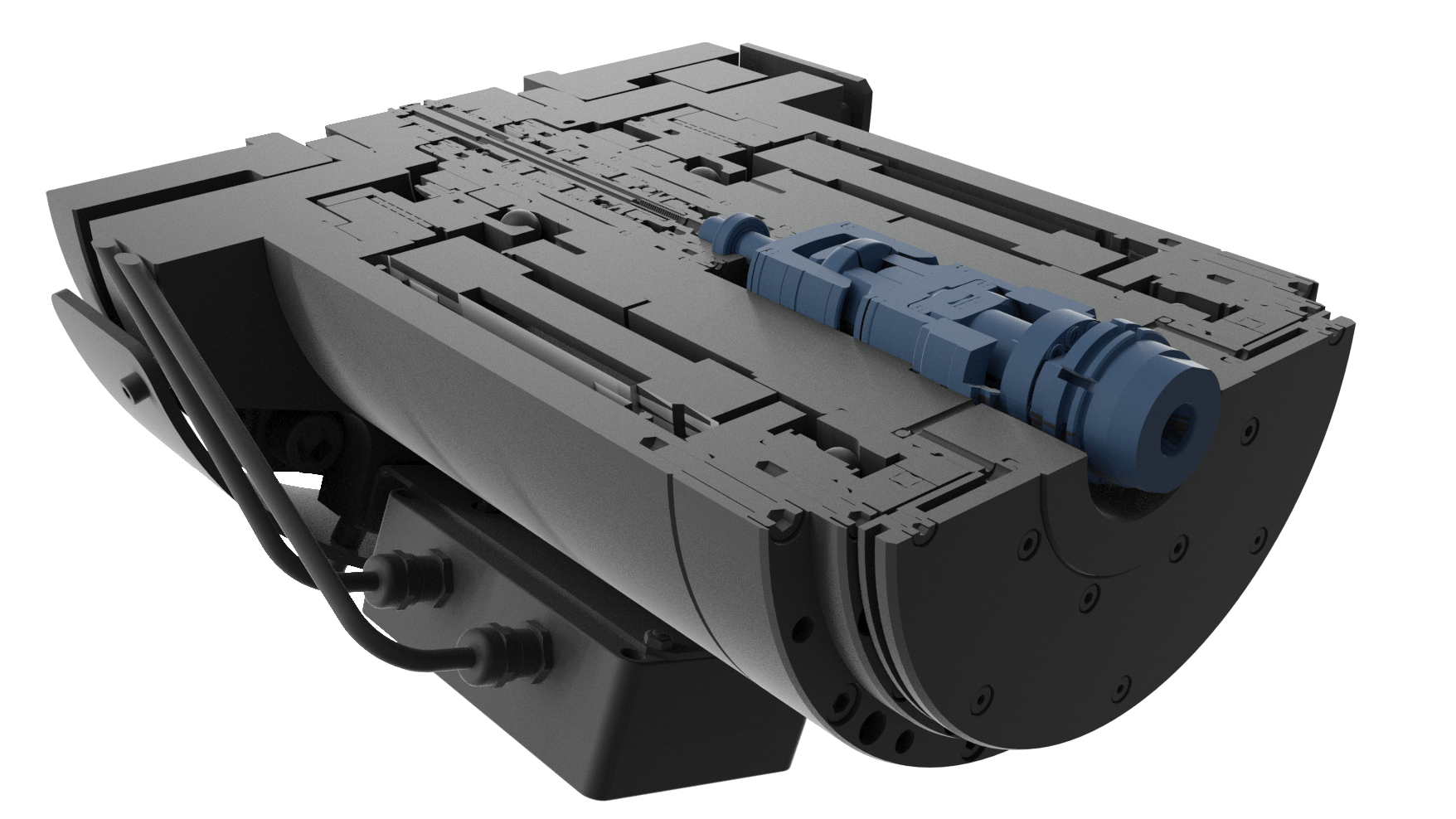

FSW fork-head. Specially designed for gantry systems

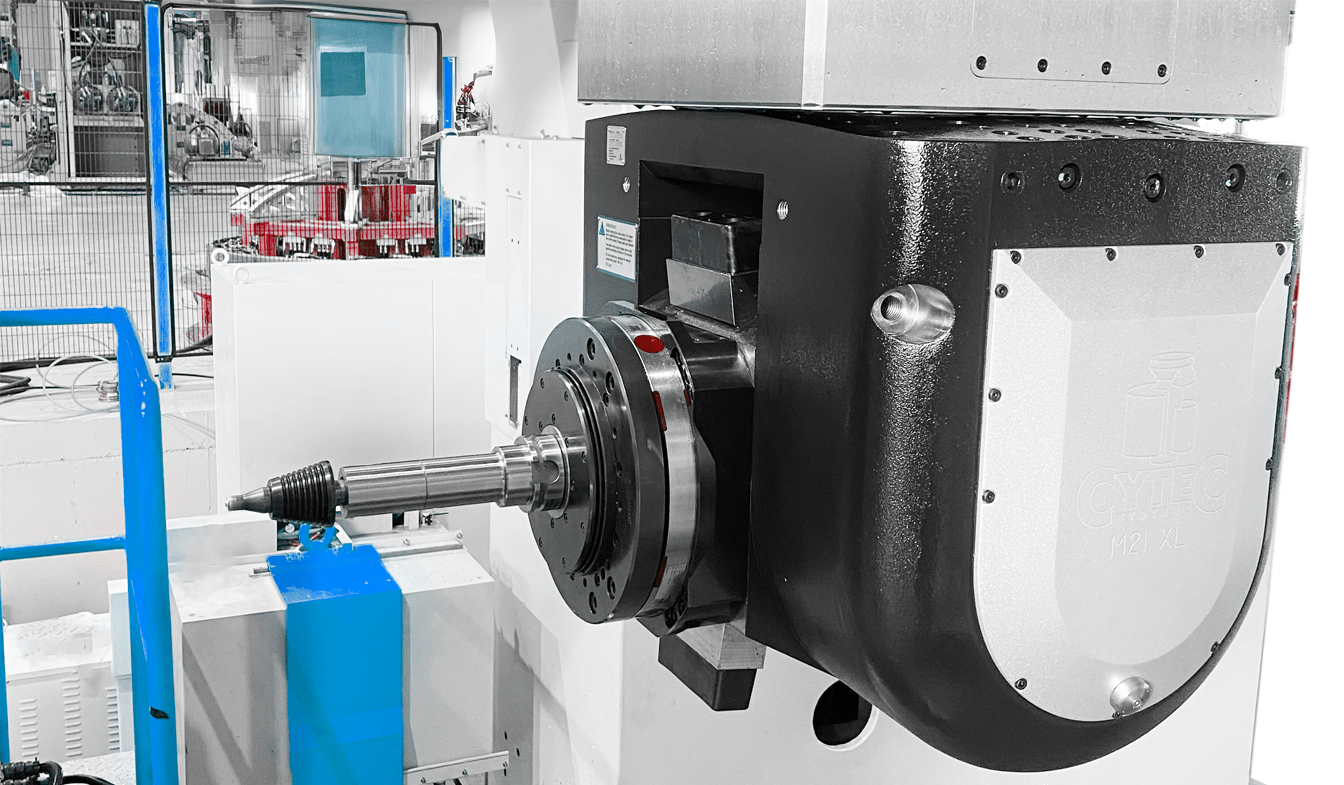

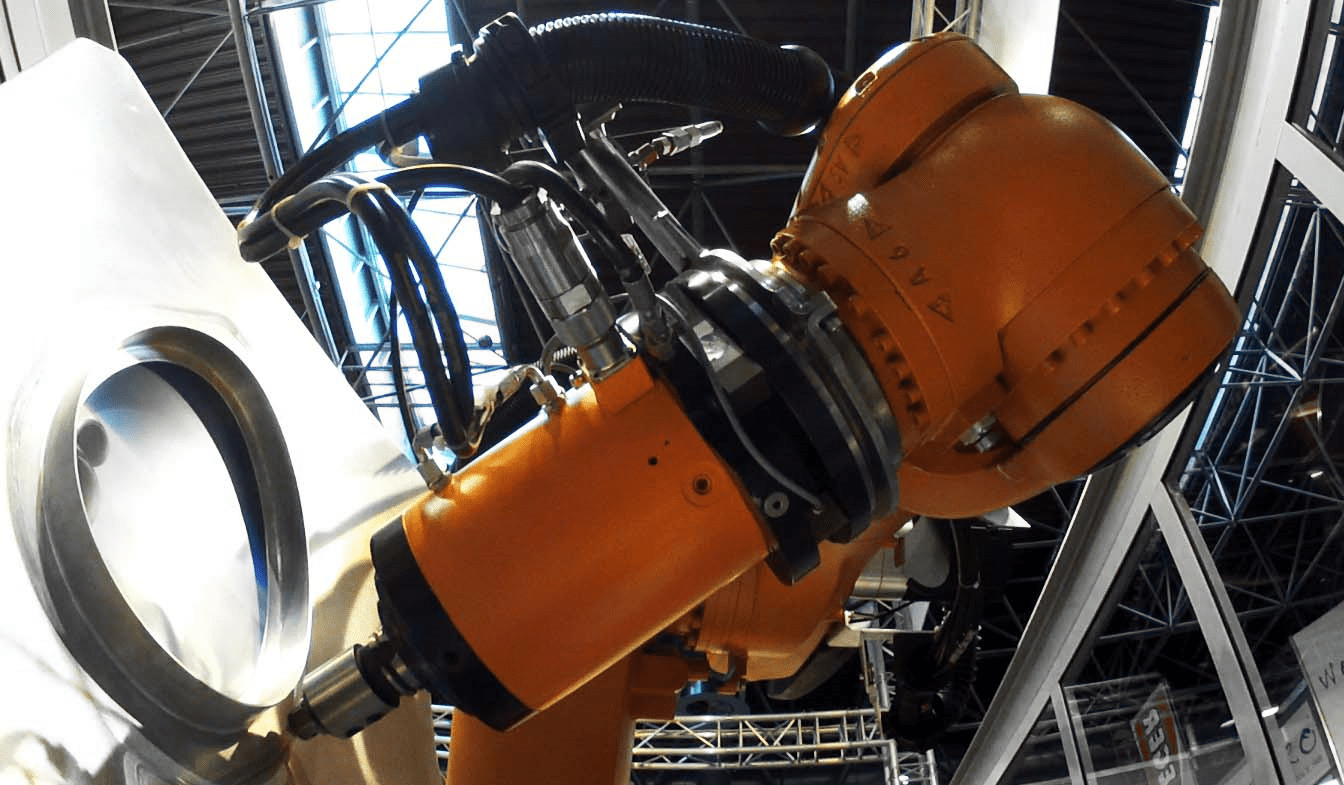

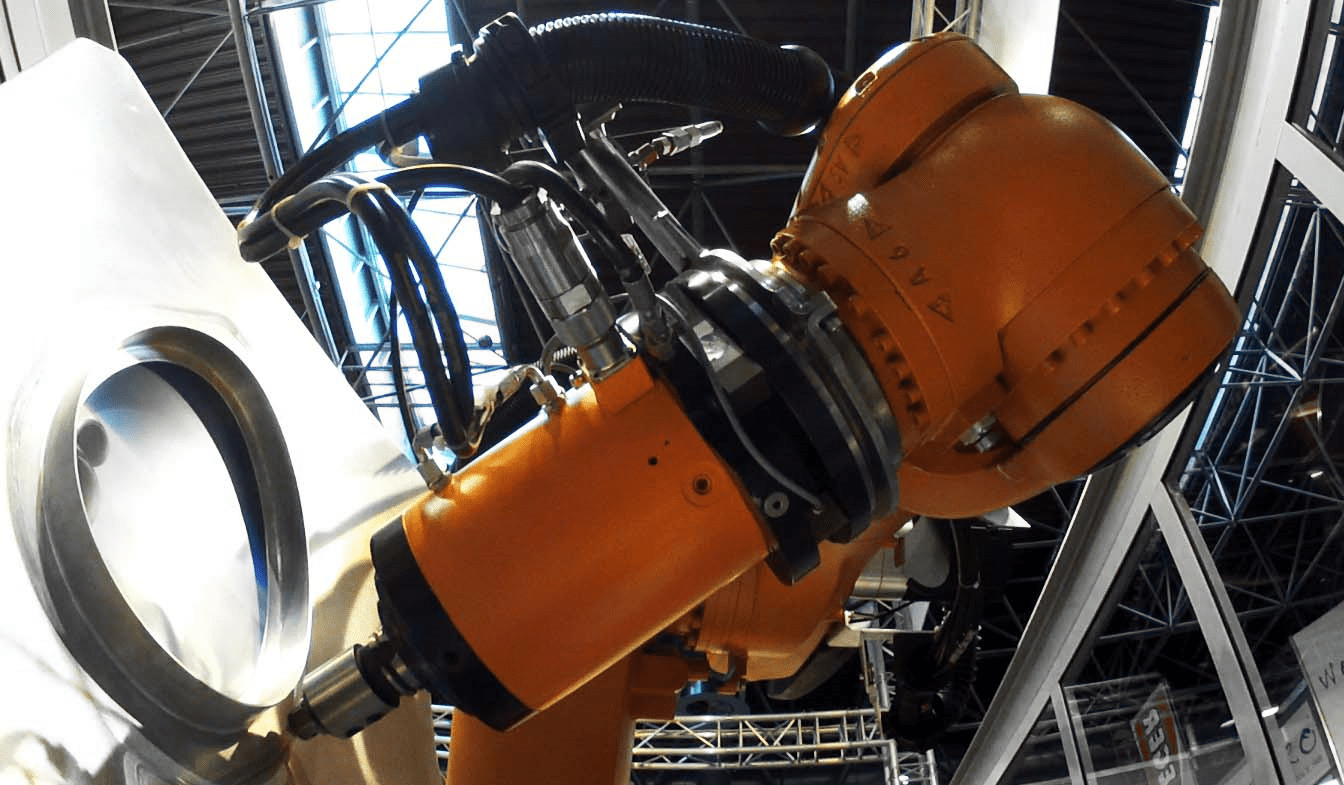

Friction Stir Welding with the Robot CyStir Motor Spindle

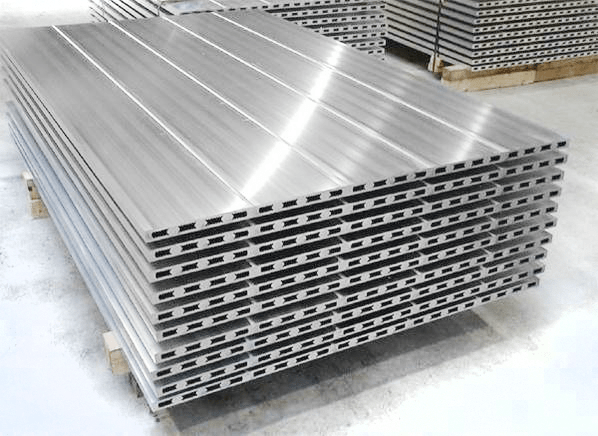

The Applications Friction Stir Welding

- Atomizer

- Aggregate

- Coil joining

- Connection of deck plates

- …and many other production parts in different markets

- Aircraft Engineering

- Space travel

- Defense

- Aircraft industry

- Automotive industry

- Fuel tanks

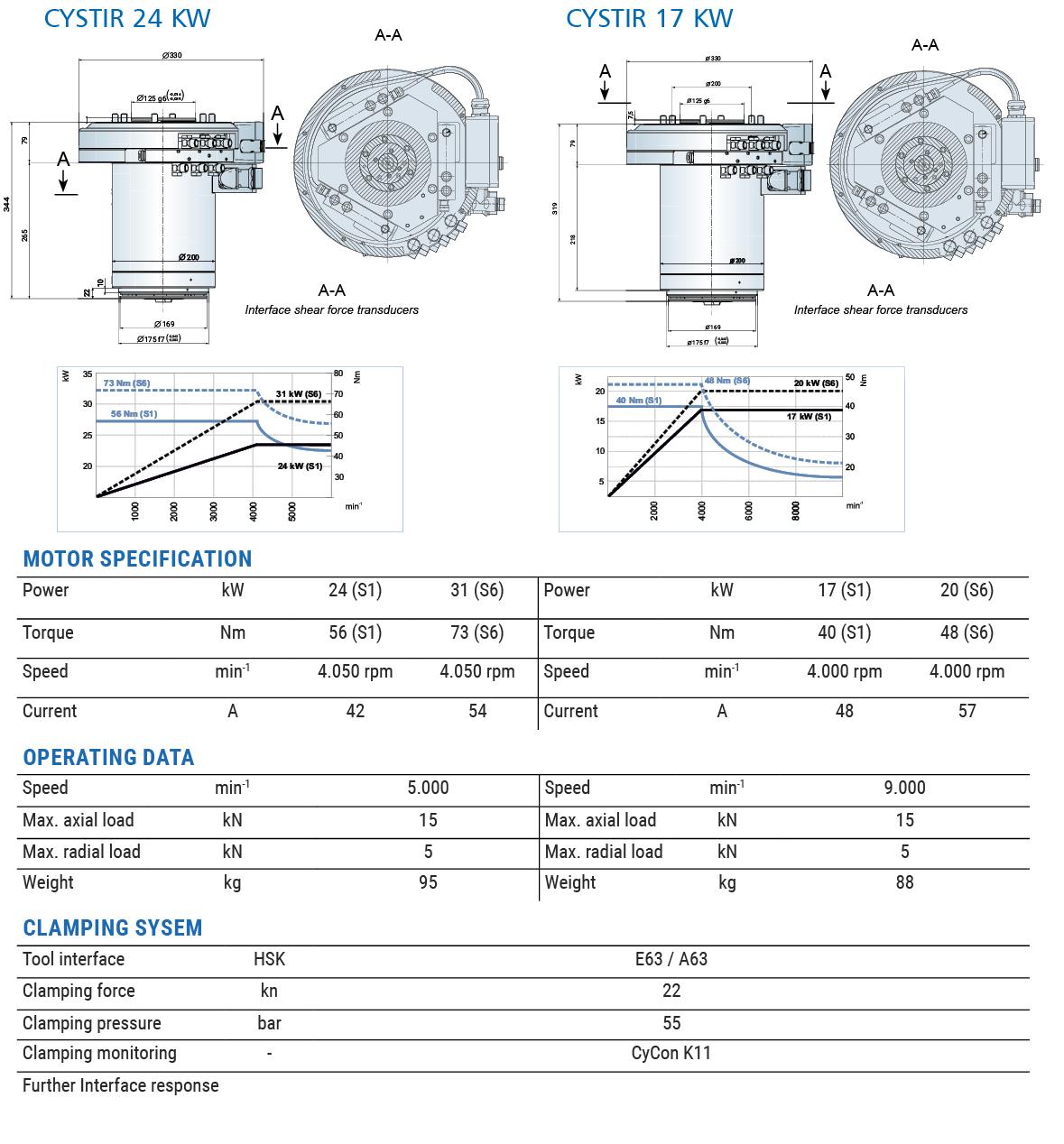

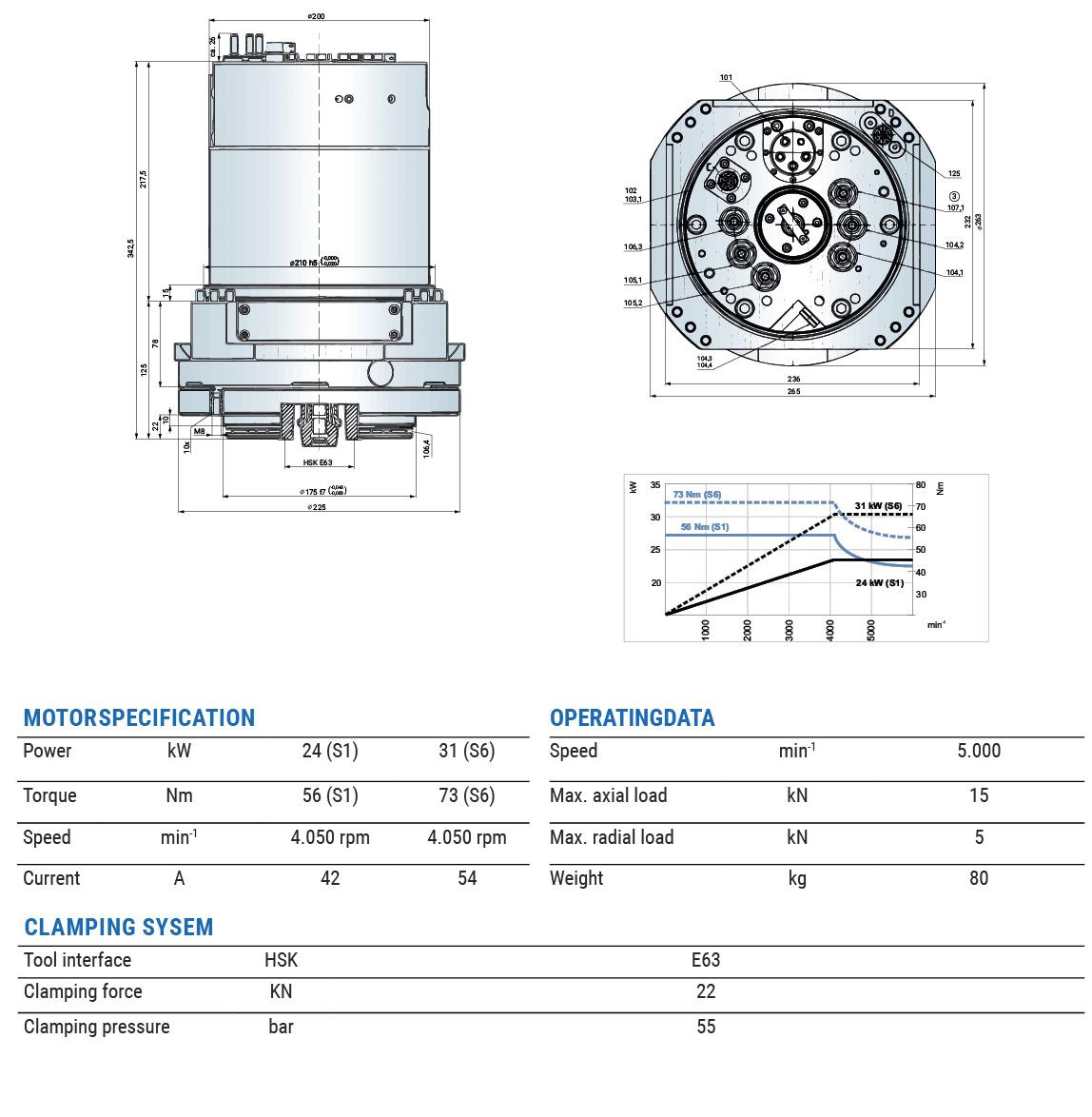

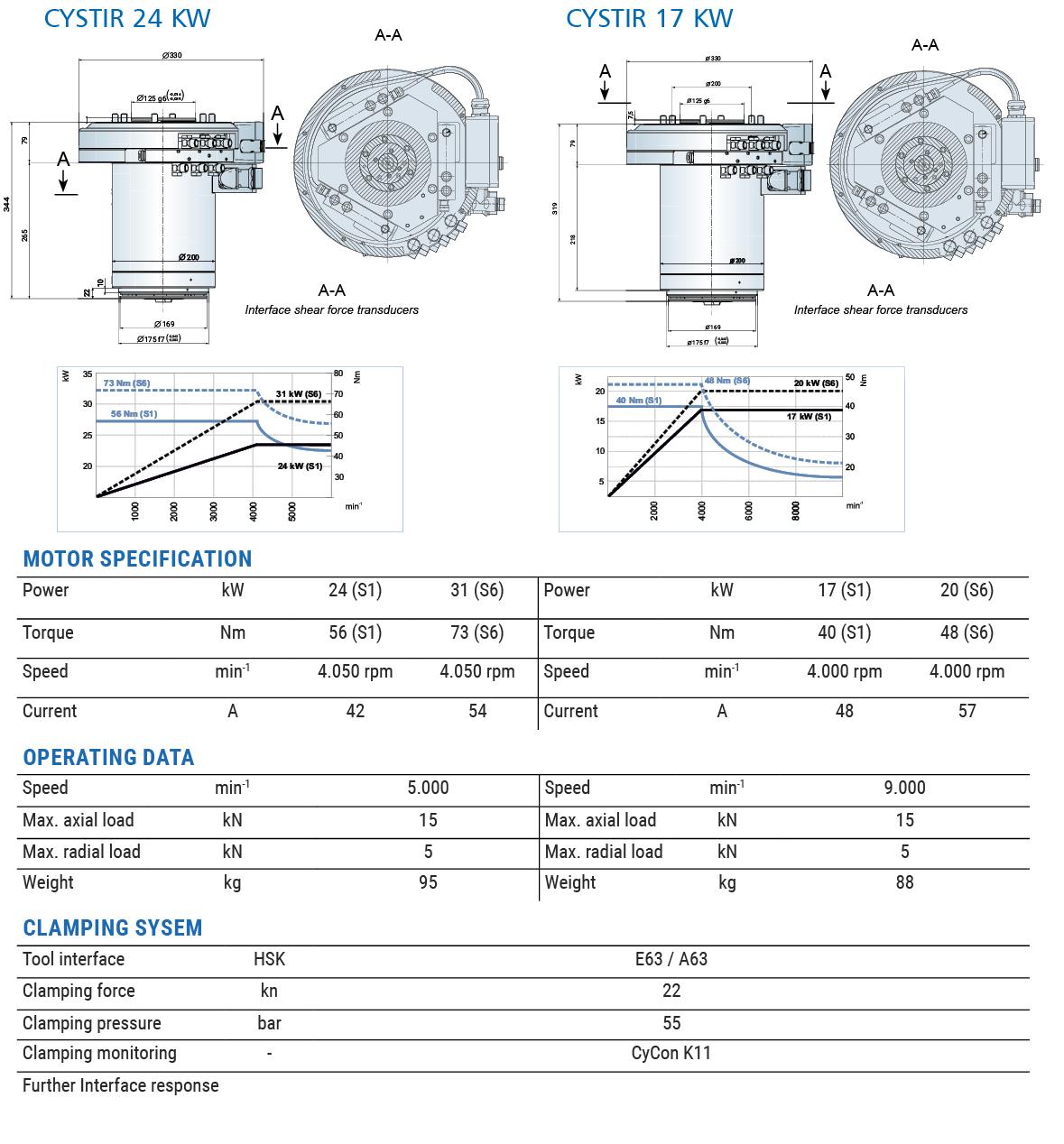

Technical Data –

FSW Spindle Systems robotic arms

Friction Stir Welding (FSW)

Technical Data –

FSW Spindle Systems FORK HEAD

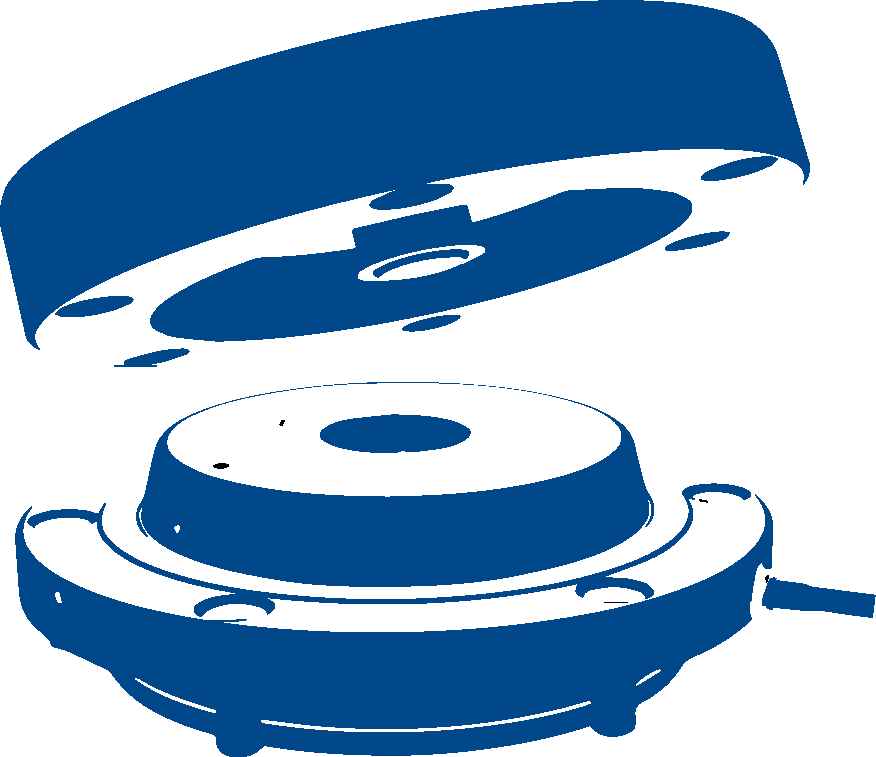

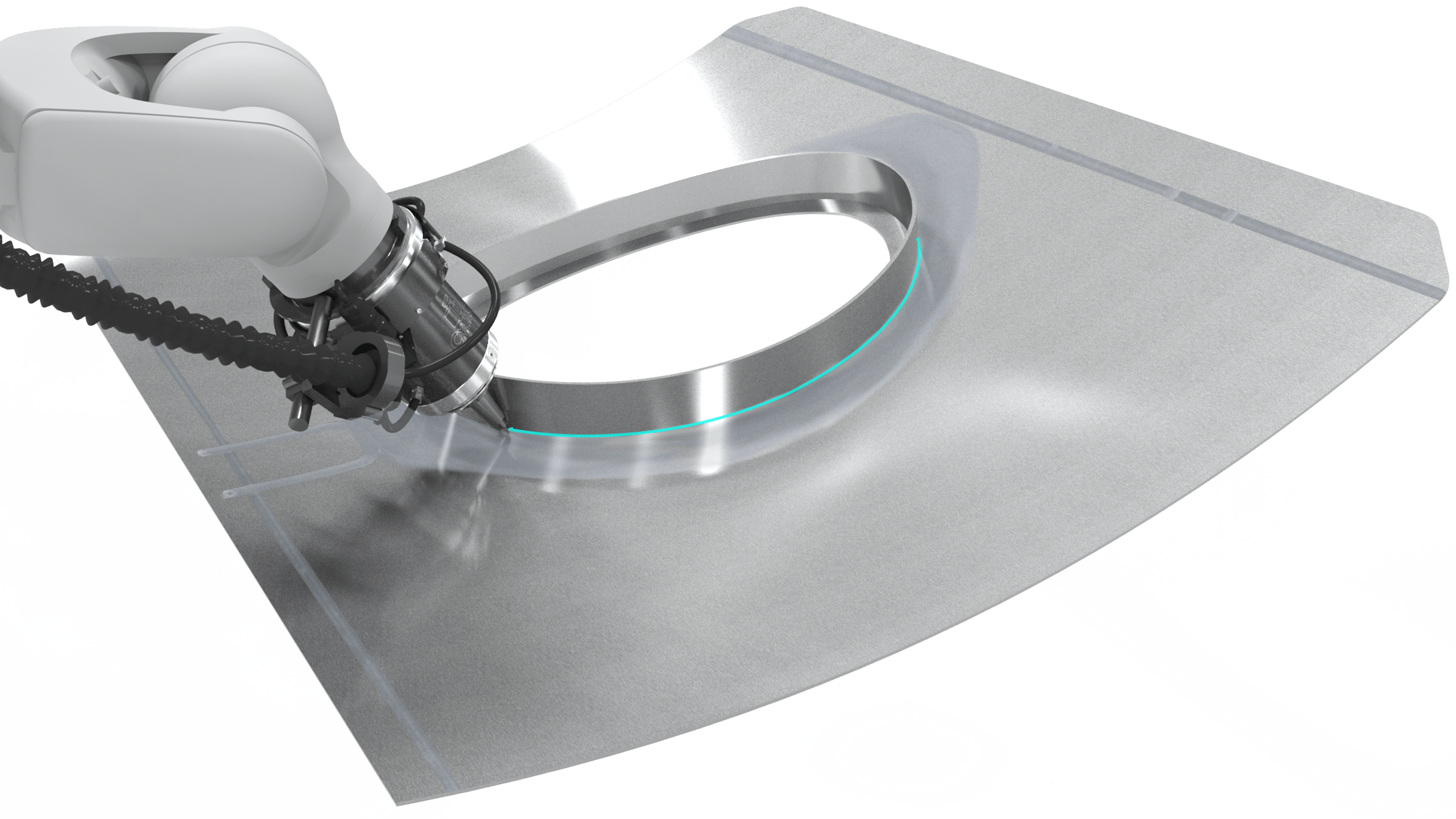

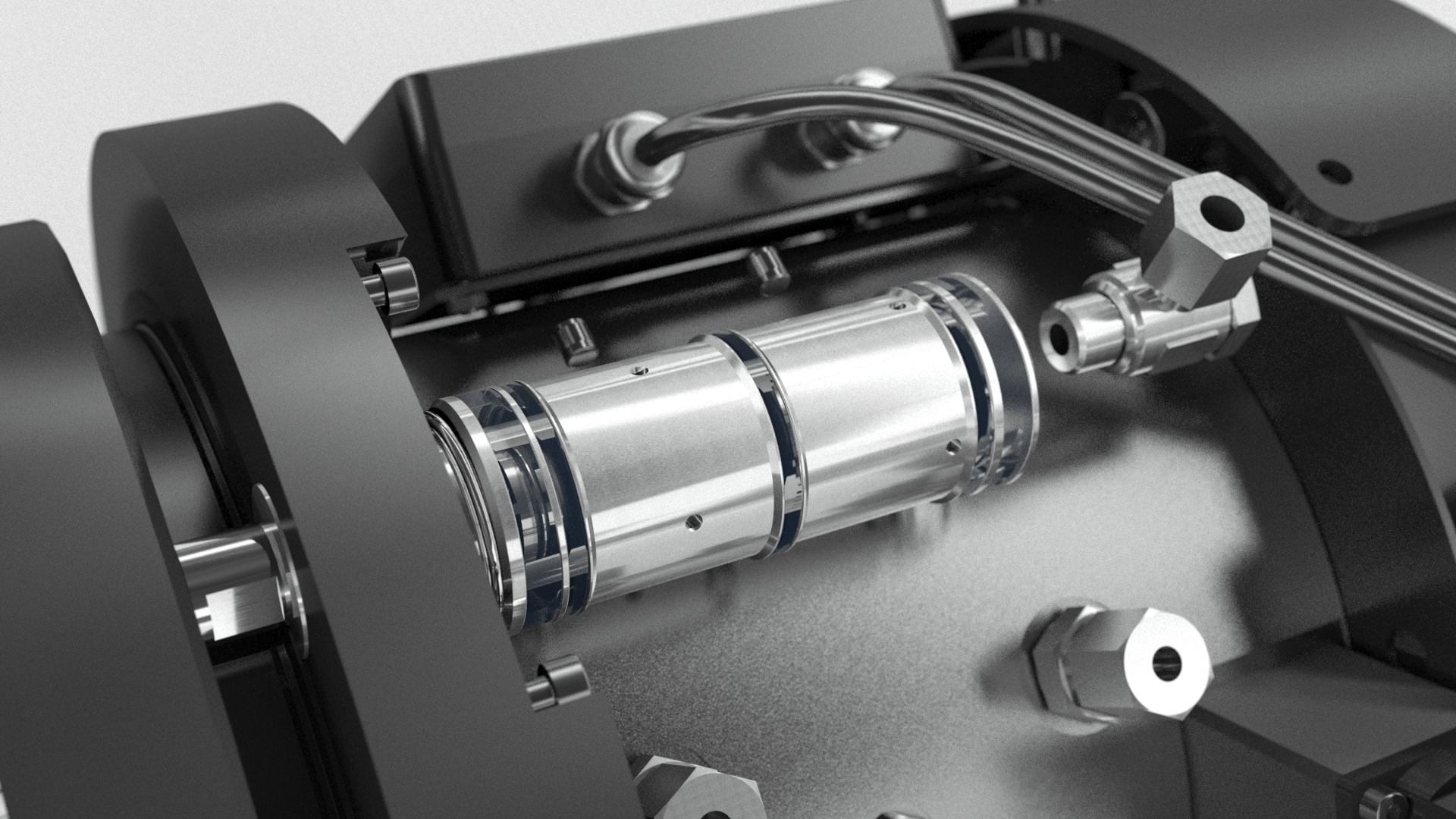

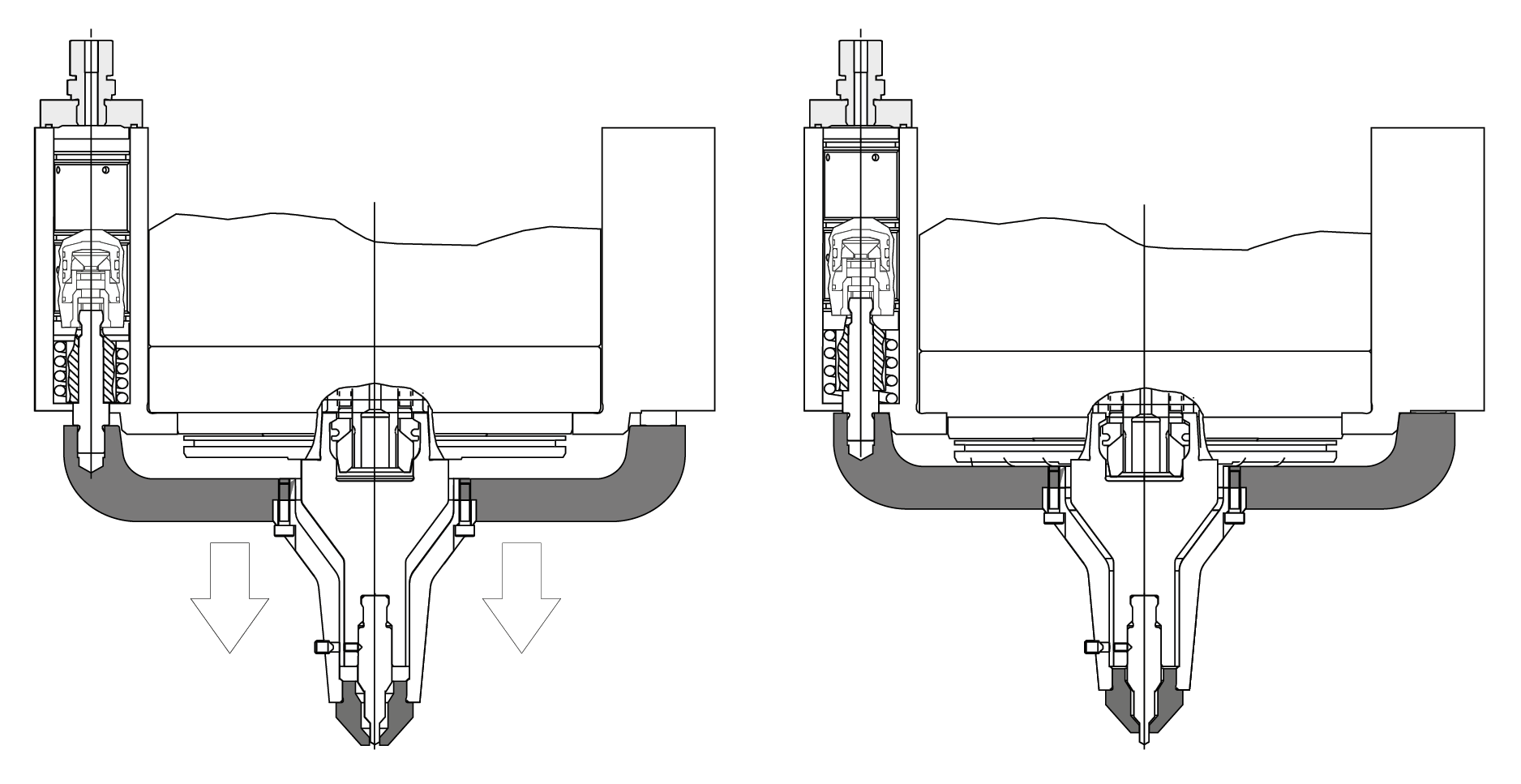

FLEXTOOL

High surface finish, less process force and heat, highly dynamic welding enabled by non-rotating tool shoulder separate retraction of the Pin or separate pushing shoulder.

This special join process is more sensitive and a good alternative to great better surface finish. The friction pin rotates into the mate-rial. The non rotating shoulder gives a slight pressure to the welding surface. This process create less force and heat. This type of FSW tool is often used on thin workpieces. With the Flextool an axial shoulder compression at the end of the welding process is possible. During the shoulder stay on the surface the Pin returns from the material.

Mounting ring with feed and clamping units (3 pcs.)

Mounting ring with feed and clamping units (3 pcs.)

Axial moving shulder

Axial moving shulder

Max. axial load:

|

15 kN |

Max. radial load:

|

5 kN |

Stroke feed:

|

6 mm |

Preloaded spring force feed unit:

|

430 N |

Max. clamping force of the clamping system:

|

3 x 11 kN |

Max. clamping pressure of the clamping system:

|

70 bar |

Weight tool pin:

|

1,2 kg |

| Weight moving shoulder: |

8,2 kg |

| Total weight: |

28,4 kg |

Characteristic spindle components

- HSK-tool interface with positive locking hydromechanical tool clamping system

- Spindle-torque motor, can be combined with all common

control systems

- pre-loaded hybrid bearings

- Shear force transducer for force regulation

during welding process

- Rotary union for transmission of clamp- and release-hydraulic

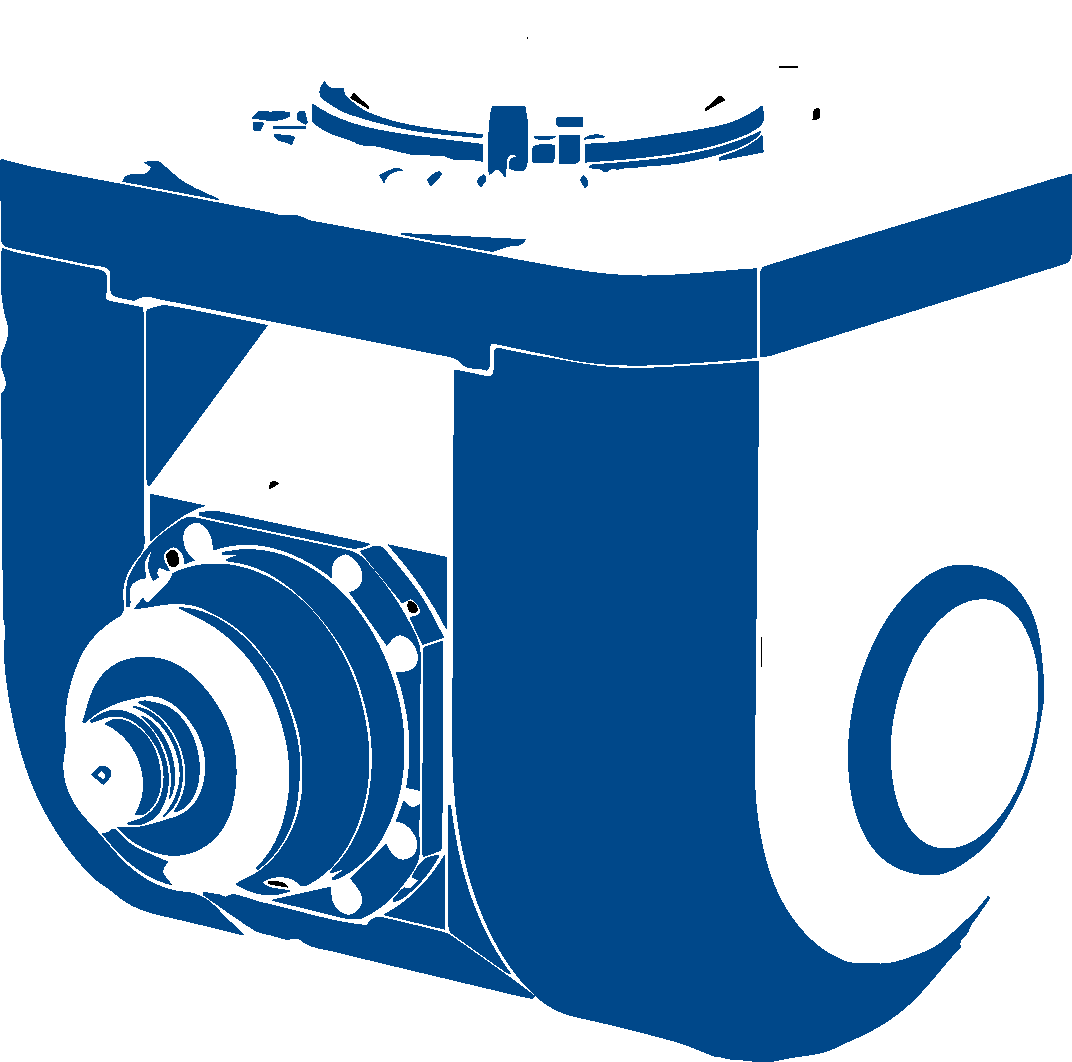

Clamping system & Control signal processing

Automatic Tool Clamping system

Cytec Friction stir welding spindles and heads are equipped with an automatic hydromechanical tool clamping system and shear force transducer for an optimal force regulation during the welding process. The Flextool and CyStir motor spindle offers further automation solutions to seal the weld seam.

The tools are inserted either manually or by a pickup station into the tool interface.

The PLC triggers the hydraulic operation to lock the tool high clamping force.

The tool clamping is controlled by an analog volume flowmeter combined with an electronic evaluation device integrated in the control cabinet.

Beispieltext. Klicke, um das Textelement auszuwählen.